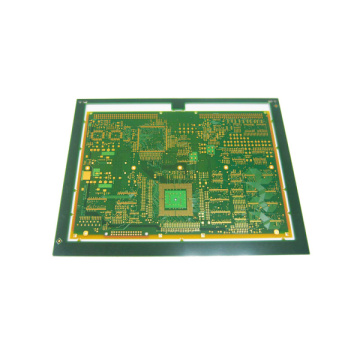

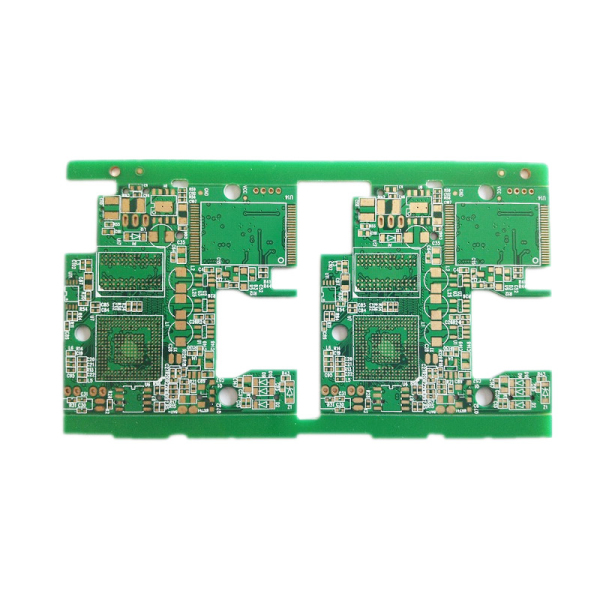

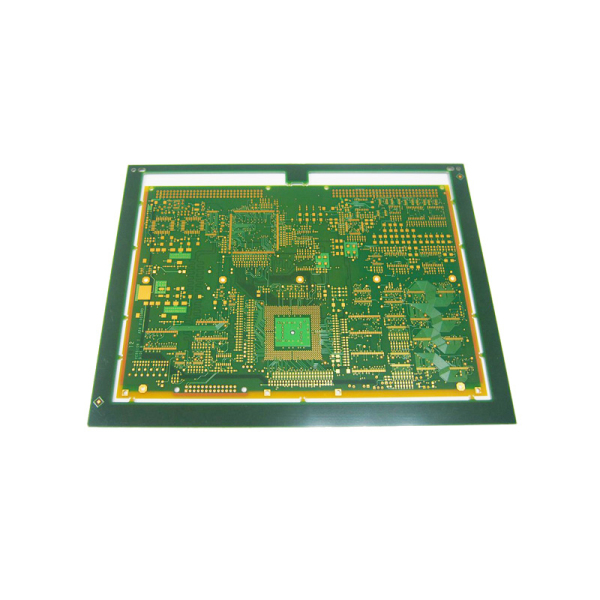

Low Cost 94v0 ROHS aluminum PCB board

Basic Info

Model No.: Low Cost PCB FR4 PCB Design

Product Description

What is the use of copper clad laminate?

High Quality Prototype PCB Fabrication must use high quality materials. High frequency board and Rigid-Flex Board are to use high-quality substrates for production, and copper clad laminates are used as learning materials. Copper clad laminate (also known as base material) is a plate-like material formed by impregnating a reinforcing material with resin, one or both sides with copper foil, and then hot pressing, called a copper clad laminate. It is the basic material for PCB, often called substrate. When it is used in the production of multilayer boards, it is also called core board (CORE).

What is the use of copper clad laminate

Used to make integrated circuits

How is the copper of the copper clad laminate made up?

The copper clad laminate is through bonding and hot extrusion processes, so that a certain thickness of copper foil is firmly covered on the insulating substrate. The substrate material and thickness of the copper clad laminate used are different.

Is the copper clad laminate a pcb board?

PCB is not the same as copper clad laminate. Copper Clad Laminate refers to a sheet with copper foil coated on one or both sides of a glued board. It is one of the raw materials for making single-sided PCB or double-sided PCB.

Classification of copper clad laminates

1. According to the mechanical rigidity of the copper clad laminate, it can be divided into rigid copper clad laminate (RigidCopperCladLaminate) and flexible copper clad laminate (FlexibleCopperCladLaminate).

2. According to different insulating materials and structures, it can be divided into organic resin-based copper clad laminates, metal-based copper clad laminates, and ceramic-based copper clad laminates.

3. According to the thickness of the copper clad laminate, it can be divided into thick plates (the thickness range is 0.8~3.2mm (including Cu)) and thin plates (the thickness range is less than 0.78mm (excluding Cu)).

4. According to the reinforcing material of the copper clad laminate, it is divided into glass cloth-based copper clad laminate, paper-based copper clad laminate, and composite-based copper clad laminate (CME-1, CME-2).

5. Divided into flame-retardant boards according to the flame-retardant grade

(Flame resistant PCB) and non-flame retardant boards: According to UL standards (UL94, UL746E, etc.), the CCL flame retardant grades are divided, and rigid CCL can be divided into four different flame retardant grades: UL-94V0 grade ; UL-94V1 level; UL-94V2 level and UL-94HB level.

Generally speaking, the copper clad laminates that have reached the flame retardant HB level are tested according to UL standards, which are called non-flame retardant boards (commonly known as HB boards). The copper clad laminate that meets the combustibility requirements of the vertical combustion method in the UL standard (the best flame retardant property is UL-94V0) is called the flame retardant board (commonly known as V0 board). The popular names of "HB board" and "V0 board" are very popular in our country's classification of paper-based copper clad laminates. In the flexible copper clad laminate, due to the difference in the method of determining the flame retardancy, when it reaches the best flame retardant rating required by UL94, it is represented by UL94-VTM-0 level (equivalent to UL-94V0 of rigid CCL) class).

6. According to some properties of copper clad laminates, it is divided into high Tg boards (Tg≥170℃), high dielectric performance boards, high CTI boards (CTI≥600V), environmentally friendly copper clad laminates (halogen-free, antimony-free), ultraviolet light Shielded copper clad laminate.

(1) Copper clad phenolic paper laminate

It is a laminate made of insulating impregnated paper (TFz-62) or cotton fiber impregnated paper (1TZ-63) impregnated with phenolic resin and then hot pressed. The adhesive tape on both surfaces can be attached with a single sheet of alkali-free glass impregnated cloth. Cover one side with copper foil. Mainly used as a printed circuit board in radio equipment.

It is a laminated product made of alkali-free glass cloth impregnated with epoxy phenolic resin and hot pressed. One or both sides are coated with copper foil. It has the advantages of light weight, good electrical and mechanical properties, and convenient processing. The surface of the board is light yellow, if melamine is used as the curing agent, the surface of the board is light green and has good transparency. Mainly used as a printed circuit board in radio equipment with higher operating temperature and operating frequency.

It is a kind of copper-clad board made of PTFE board as the substrate, covered with copper foil and hot-pressed. Mainly used for high frequency (High frequency board) and UHF circuits as printed boards.

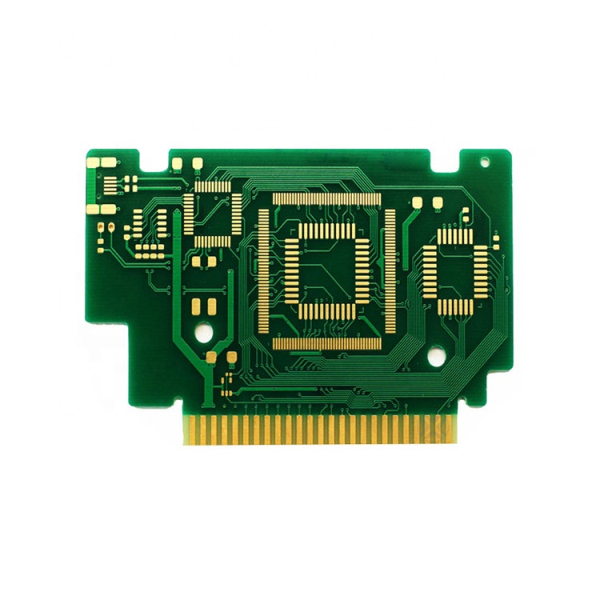

(4) Copper clad epoxy glass cloth laminate

It is a commonly used material for hole metallization (Metal Core PCB) printed boards.

(5) Soft polyester copper-clad film

It is a ribbon-shaped material made of polyester film and copper by hot pressing, and it is crimped into a spiral shape and placed inside the device during application. In order to reinforce or prevent moisture, it is often poured into a whole with epoxy resin. Mainly used for Custom Flexible PCB fabrication and printed cables, and can be used as a transition line for connectors.

Product Categories : Quick Turn PCB > 12 Hours For 2 Layer PCB